In the realm of electronic devices, maintaining optimal performance while managing heat dissipation is a critical challenge. As technology advances, devices become more powerful and compact, resulting in increased thermal loads that can lead to overheating. This makes effective thermal management solutions essential for ensuring device reliability and longevity. One such solution gaining prominence is the use of tungsten copper heat sinks.

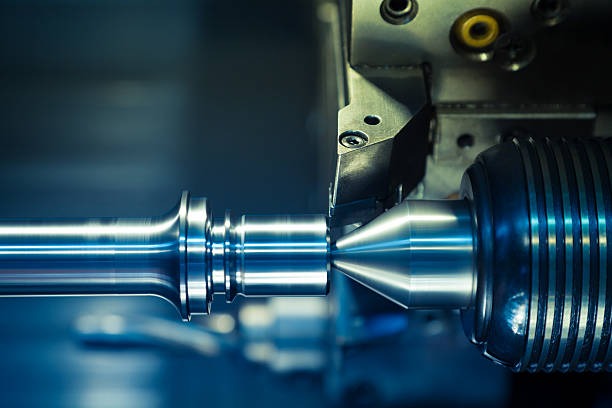

Tungsten copper heat sinks are composite materials that combine the high thermal conductivity of copper with the low expansion coefficient of tungsten. This unique combination offers several advantages over traditional heat sink materials like aluminum or pure copper. The primary benefit is their excellent ability to conduct and dissipate heat efficiently, which helps in maintaining lower operating temperatures for electronic components.

The integration of tungsten and copper results in a material that not only conducts heat effectively but also maintains structural integrity under extreme conditions. Tungsten’s low coefficient of thermal expansion ensures that the heat sink remains stable even when subjected to rapid temperature changes, preventing damage due to thermal stress. Meanwhile, copper’s high thermal conductivity allows for quick absorption and dispersion of heat away from sensitive components.

One area where tungsten copper heat sinks demonstrate significant impact is in high-performance computing environments. In https://amt-mat.com/understanding-tungsten-copper-heat-sinks servers and data centers, where processors generate substantial amounts of heat during operation, efficient cooling mechanisms are crucial to prevent throttling and ensure consistent performance. Tungsten copper’s superior properties make it an ideal choice for these applications by facilitating better cooling efficiency compared to conventional options.

Moreover, as electronic devices continue to shrink in size while increasing in power density, the need for miniaturized yet highly effective cooling solutions becomes apparent. Tungsten copper’s ability to be fabricated into complex shapes without compromising its conductive properties makes it suitable for modern electronics where space constraints are prevalent.

Beyond computing applications, tungsten copper heat sinks find utility in aerospace industries as well as telecommunications equipment where reliability under fluctuating environmental conditions is paramount. Their resilience against oxidation at elevated temperatures further enhances their suitability across various sectors requiring robust thermal management solutions.

However, it’s important to note that while tungsten copper offers remarkable benefits, considerations such as cost implications must be weighed when opting for this material over more traditional alternatives. Despite this factor, its long-term advantages often justify initial investments through improved device performance and reduced maintenance costs associated with overheating issues.

In conclusion, optimizing device performance through advanced materials like tungsten copper presents a promising avenue towards achieving enhanced reliability and efficiency across diverse technological landscapes. By effectively managing thermal challenges inherent in modern electronics design, these innovative solutions pave the way for continued advancements without compromising on durability or functionality.